Parts of a Beehive

What are the different parts of a beehive and what is required to run a hive of bees? Well, that depends on who you ask. Many different opinions exist about the woodenware you need to keep bees. We have always tried using as few pieces as possible and still maintain productive and healthy hives. The more pieces of equipment you use, the less efficient you become. It may not be an issue with a couple hives, but if you have hives hives to maintain and inspect, you need to stay efficient. Every piece you add to a hive, has to be cleaned from time to time. Not to mention all the extra handling every time you inspect a hive.

Two simple operational changes we have made is to get rid of inner covers and feeding covers. They are sometimes the same piece of equipment and are often used as a standard cover in summer with the feeding cap plugged when not feeding. We made insulated covers that have a feeding hole and they stay on the hives at all times. This one piece can replace up to 2 other pieces; the inner cover and a feeding cover.

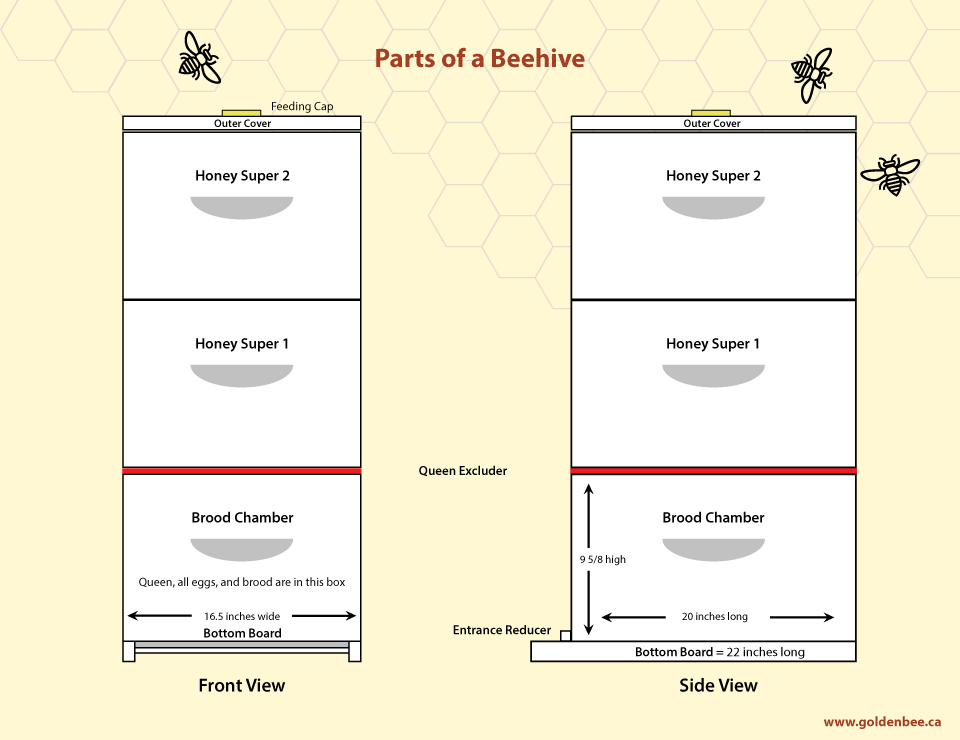

Below is a diagram of our hive model.

The following six pieces of equipment are required for each hive:

- A bottom board

- Entrance reducer

- Brood box

- Queen excluder

- 4-5 honey supers per hive

- Outer cover

It is our opinion that you do not need inner covers or top entrances for your bees. Adding on extra pieces of equipment is time consuming and more costly and is not necessary.

We will add top entrances on some hives to see if there are difference in the amount of cured honey, but have never noticed anything worth noting. Bees appear to do just fine with one entrance on the bottom. On the warmest summer days, you can provide an upper entrance by simply leaving a small gap between the top box and outer cover.

Let us examine what each piece does.

- The bottom board is the bottom piece that the brood chamber sits on. It’s the same width as a regular box but it’s 2 inches longer and sticks out in front. That is the landing board so bees can land or cluster just outside the hive. The bottom board has 2 vertical pieces on which the box rests and a solid plywood as the bottom. The vertical pieces allow 7/8 inch clearance to vent the hive. This is very important during summer when air needs to circulated. Bees fan air into the hive on one side and air is usually pushed out on the other side of front. A puff of smoke will show which way air is being moved into the hive.

- The entrance reducer is simply a piece of wood that blocks most of the entrance but leaves a small section open in front. It is only used when it’s cold or during robbing season to restrict the entrance. This allows bees to defend a smaller opening against other bees or pests. It can also be used to completely block the entrance to keep bees locked inside when moving a hive. It is not recommended locking them in when weather is hot due to overheating.

- The brood box is the box where the queen lays the eggs. It is typically a single box on the bottom or two boxes if the beekeepers uses doubles brood chambers. Brood chambers have 10 frames in them. Some beekeepers use 8 frame equipment so they would only have 8.

-

A new queen excluder. Worker bees can fit through but queens can’t. The queen excluder is a metal or plastic ‘grate’ that covers a box and allows worker bees to get through. The queen, due to her larger size, is unable to get through. The keeps the queen confined to the brood chamber. Sometimes smaller queens will be able to get through and then you have eggs in the honey supers.

- Honey supers are the same size (length and width) as brood chambers but the height can vary. Honey supers are very heavy when they are full so beekeepers may opt for shorter boxes reducing the weight of each box. Honey supers have 9 frames in them and deep supers can weigh up to 85 pounds when full of honey.

- The outer cover is the lid of the hive. We use insulated lids with a metal covering to ensure they are long lasting. Different types of outer covers exist like the telescoping lid that has a lip all around box. The migratory lid only has a lip front and back and are used for hives that are moved a lot. Our lids are exactly the same size as the hive so they can be pushed together in colder weather. The insulation also helps maintain hive temperatures, in both cooler and warmer weather.

You want to maintain as much standard sized equipment as possible. The standard size for a 10 frame deep box is 16.5 inches wide by 20 inches long and 9 5/8 high. We use 7/8 wood and not 3/4 to give us a bit of extra strength for the 85 pound honey boxes.

What pieces of equipment do you use?