Step 4: Extracting

When the cappings are opened, the frames are put into a honey extractor. The extractor spins the frames and the centrifugal force pushes the honey out of the comb. The honey is collected at the bottom of the extractor, filtered, and pumped into a holding tank.Step 1: Remove the Supers

The first step is to remove the supers fulled with honey. This is done manually. We then wait until all the bees have left the supers before taking them home for extracting.

Step 2: Warm the Supers

Once the honey supers are home, we place them into the hot room. All honey boxes are heated to 35 Celcius because warm honey flows better than cold honey.

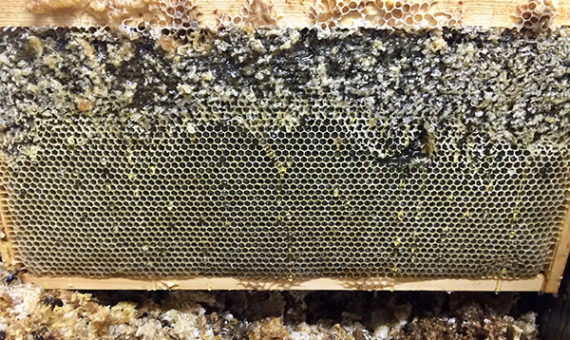

Step 3: Open the Cappings

Beeswax is waterproof and bees know it. Bees cap all ripe honey with a beeswax coating and these have to be opened if you want to get the honey out of the comb. The cappings are opened either by hand or a machine called an ‘uncapper’.

Step 5: Bottling

Once honey has been filtered, we start the bottling process. Honey gets put into 500g jars, 1kg jars or bulk pails. We will also begin our creaming process when the temperature is cooler.

Step 6: Enjoying

After all the hard work, you can enjoy the fruits of the labour. The honey is ready to be sold and used on toast, sweeten your tea or in baking.

Stay in Touch with us

Subscribe to our Newsletter for exclusive discounts and offers.